“Heating, ventilating and air conditioning systems (HVAC) account for more than 40% of the total energy used in North America and 30% worldwide.” Source. Unfortunately, the prices for energy are predicted to only go up from here and with no sign of leveling out. Standard HVAC systems have filters that cause 60% of the energy cost, just to move the air through the system. This is because the air filters create a barrier to the airflow and cause the fans to have to work harder to push the air through the filter. The dirtier the filter because, the more resistance is increased, the more energy is increased. The more stages of filtration needed in a system, the more energy costs soar. Places that use multiple stages of filtration are in search of specific needs, such as semiconductors or pharmaceutical manufacturing facilities. Facilities like these or like hospitals require the use of HEPA filters which use up to three or four times the power to move the air through the filtration systems.

Along with the energy usage, buildings have to maintain these air filtration systems. However, when buildings are modified, the HVAC systems are usually overlooked. Most people don’t realize the importance of examining the air filtration systems.

There are many different kinds of filters that can be used in different building and facility settings depending on industry and company needs. The chart below can be used to help you decide what type of air filtration is necessary for your business or situation.

| Application | MERV |

| Light duty residential for coil or heat exchanger protection, light commercial for the protection of HVAC and industrial equipment. | 1 to 4 |

| Superior residential for removal of allergens, light duty commercial, split systems, and roof tops. | 5 to 8 |

| Superior residential for removal of allergens, commercial office buildings, and institutional. | 9 to 11 |

| Superior commercial office buildings, superior institutional, removal of respirable particles | 12 to 13 |

| General hospital areas, low-level surgical suites, smoke removal, superior commercial buildings. | 14 to 15 |

| High-risk surgical suites, hazardous material capture, cleanrooms, HEPA level protection. | 16 to HEPA |

Filter Efficiencies & Corresponding Values of Current Filter Testing Standards

| MERV ASHRAE 52.2 | Dust Spot Efficiency ASHRAE 52.1 (defunct standard) | Arrestance ASHRAE 52.2 | Selected Eurovent EN779 Values |

| 1 | < 20 | > 65 | G1 |

| 2 | < 20 | ≥ 65 | G2 |

| 3 | < 20 | ≥ 70 | G2 |

| 4 | < 20 | ≥ 75 | G2 |

| 5 | 20 | 80 | G3 |

| 8 | 30-35 | 92 | M5 |

| 9 | 40-45 | 94 | M5 |

| 11 | 60-65 | 97 | M6 |

| 13 | 80-85 | 99 | F7 |

| 14 | 90-95 | 100 | F8 |

| 16 | 99 | 100 | F9 |

“MERV is Minimum Efficiency Reporting Value per ASHRAE 52.2, Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. Dust Spot Efficiency and Arrestance are values from ASHRAE 52.1, Gravimetric & Dust Spot Procedures for Testing Air Cleaning Devices Used in General Ventilation for Removing Particulate Matter EN779 is the European Filter Testing Standard, Particulate Air Filters for General Ventilation.”

There are many factors for selecting the correct filter and there are many types of filters: flat panel pad, fiberglass throwaway, pleated panel prefilter, bag filters, etc. This is something to discuss with your filter manufacturer since they will have the best understanding and knowledge to help you with each individual situation you are dealing with.

“Another determining factor for longer life and lower energy usage relates to configuration losses. Each filter has construction components that restrict airflow. A properly manufactured filter does not have air pockets that can cause turbulent airflow and increase resistance. Additionally, media spacing must be dynamically optimized so air flows through the filter freely even as the filter loads with the contaminant. It is also important to maintain media exposure while loading with contaminant through the use of

- tapered pockets on bag filters

- tapered deep pleats on box filters

- and, radially configured pleats as opposed to v-style pleats on medium efficiency prefilters

Filters are only one component of an HVAC system, albeit one of the most important.” Source.

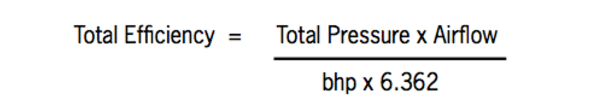

Energy Calculation

To calculate the energy cost to move air through any component in your system, the following equation applies:

- Volumetric Flow Rate “Q,” stated in cubic feet per minute

- Total Pressure in inches of water (resistance due to the friction of ducts, coils, filters, etc.) and △P of the component under consideration.

- Density factor of the gas being collected “df” (dimensionless).

- Efficiency of the fan, (dimensionless).

These are combined into the air power equation:

Power (horsepower) = ![]()

(Small reductions in the numerator can have a significant cost impact.)

The actual equation for complete efficiency is:

Where:

Total Pressure is in inches of water

Airflow is in cubic feet per minute (cfm)

Bhp is brake horsepower

Another factor in choosing an air filter is the Energy Cost Index (ECI). This tells you whether the filter will provide the efficiency level published throughout the entirety of the life of the filter. “Some filters use an electret charge to enhance efficiency, but the charge dissipates over time, and the filter’s efficiency drops.” Source. The best rating is five stars and indicates that the filter given that rating will be one of the most energy-efficient and longest-lasting filters available.

Camfil is known for their superior quality of air filters and their top of the line air filtration systems that provide the best and cleanest air possible, with the most green option on the market. “Camfil is the world’s largest and leading manufacturer of filters and clean air solutions… We can be found everywhere from offices to clean rooms for sensitive electronics production, pharmaceuticals, mines, factories, hospitals and nuclear power stations.” Source.

Camfil has a strong belief in providing clean air for people around the world. They are a global company with 29 subsidiaries, as well as 23 production plants throughout the world. Despite being so international, they make sure they have local agents available for their customers in every place possible.

“For you as a customer, this means that you stand to benefit from our global knowledge bank and the resources that a world-leading company constantly invests in research and development. At the same time, you stand to benefit from personal contact with your local Camfil office, which will be only too pleased to provide you with the right filter solution for your particular needs.” Source.

Some Camfil Trademarks

| Farr 30/30 | Absolute |

| Aeropac | Aeropleat |

| Cam-Flo | Camsorb |

| Campure | Durafil |

| Dynavane | Filtra 2000 |

| Gigacheck | Gigalam |

| Gigapleat | Glide/Pack |

| Hi-Flo | HP |

| Micretain | Opti-Pac |

| PharmaSeal | Riga-Flo |

| Riga-RP | Riga-Sorb |

| Sidelock | Turbopac |

| Ultra-Pac |

Thank you for your interest in improving indoor air quality and for your support of Camfil.

Media Contact:

888.599.6620